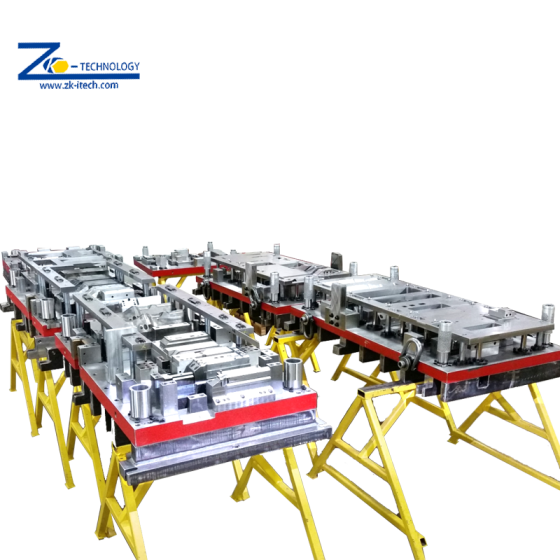

Automotive Metal Pressing Die

The dies used in automotive stamping has to be precise and accurate because when the external shell of the car or motor vehicle is inspected then there should not be asymmetrical or any rough parts on the outer body of the vehicle. The appearance of the motor vehicle must be perfect with no defects.

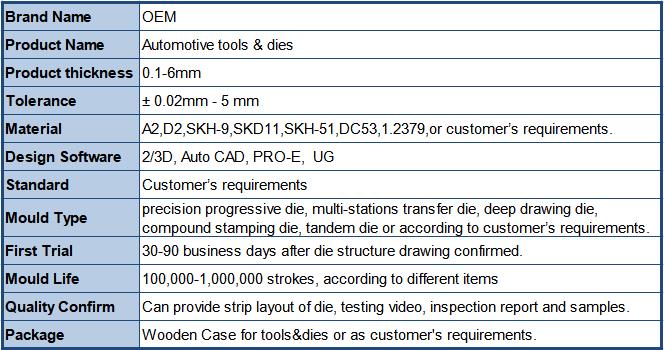

- Information

The quality of the automotive stamping dies whether it is for the exterior or the interior parts of the motor vehicle must be of the highest grade. This leads us to the next point as to how using metal stamping in automotive stamping dies can be advantageous.

Reduce production time:

Metal stamping helps in reducing the time that is required for production of automotive stamping dies because in a very short period of time more parts can be manufactured.

High quality:

Metal stamping can manufacture huge volume of parts for both the exterior and interior of motor vehicle at a high speed and it can do this accurately without compromising on the quality of the product. Hence, without sacrificing on the quality of the product metal stamping is the best for automotive stamping dies.

Reduce material waste:

Another benefit of using metal stamping for automotive stamping is that there is almost very low wastage. This is because when designing or shaping parts for a vehicle, metal stamping stations use the entire metal sheets for manufacturing which in turn helps to lower the overall cost of the product.

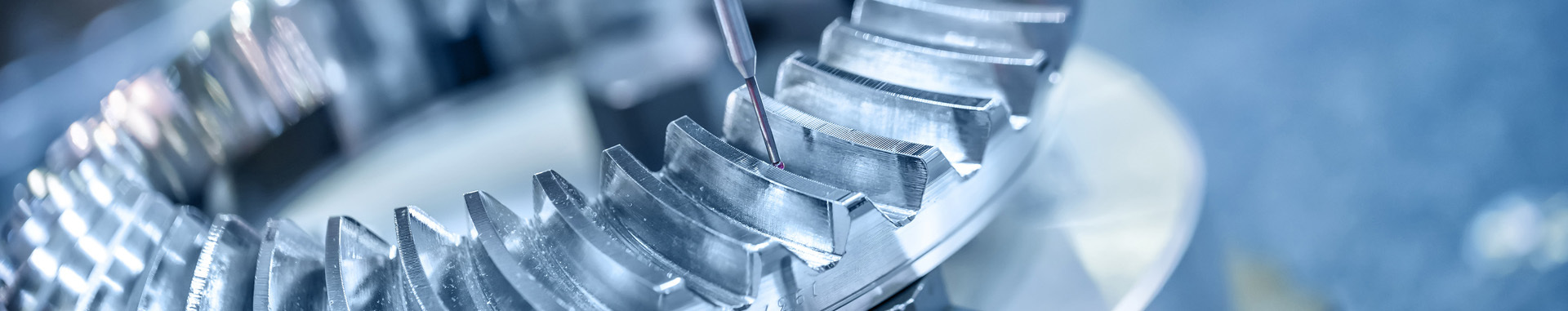

Precise:

However complex or intricate the design of the product is, metal stamping is amazing when it comes to precision. Since metal stamping maintains high quality it makes it so precise that there are hardly any errors in the final finished product and fewer parts that get damaged or faulty.

Quick design changes:

In metal stamping it is easy to update a design quickly and also to capture a die structure for other projects that can be used in the future. So it is a big save to the automotive stamping when immediate changes have to be made for the outer panel or for the small parts in a motor vehicle.

Reduce downtime:

Metal stamping is known for a long production run and so it is a continuous process which manufactures automotive dies. Frequent maintenance also enables to reduce any repairs which help to minimize the downtime.

Our advantages

Professional development and design ability

We have an experienced research and development team, and complex, difficult molds can be rapid molding and design accurately.

Quality assurance

The company has advanced testing equipment and strictly implements ISO9001 and IATF 16949 certification.It is possible to eliminate any quality problems in production.

Accurate delivery

We have the first-class advanced processing equipment, effectively ensure the rapid response and efficient service.

Business introduction

ZK specializes in designing and producing of various metal stamping tooling, and is good at producing the precision metal stamping parts.

Our company is developed steadily since its establishment with the hard work of the professional designers and all the other staffs. Nowadays, we are able to produce different kinds of hardware stamping tooling and auto-parts stamping tooling, like progressive tooling, continuous drawing tooling, machine-hand transfer tooling, etc. We are well experienced in producing tooling for stamping machines' capacity from 60 Tons till 800Tons.

At present we are able to undertake the batches of tooling development business, especially plenty experience and mature technology in designing and producing auto-parts and electric appliance parts. We will provide series service in tooling designing, developing, producing and parts production. In order to meet the developing requirements of our customers, we import the advanced machinery and the qualified technicians timely.

ZK through measure the parts to determine that the parts meet the tolerance range required, and then deliver them to customers by sea/land/air and other means of transportation according to the different packaging methods required by different customers.