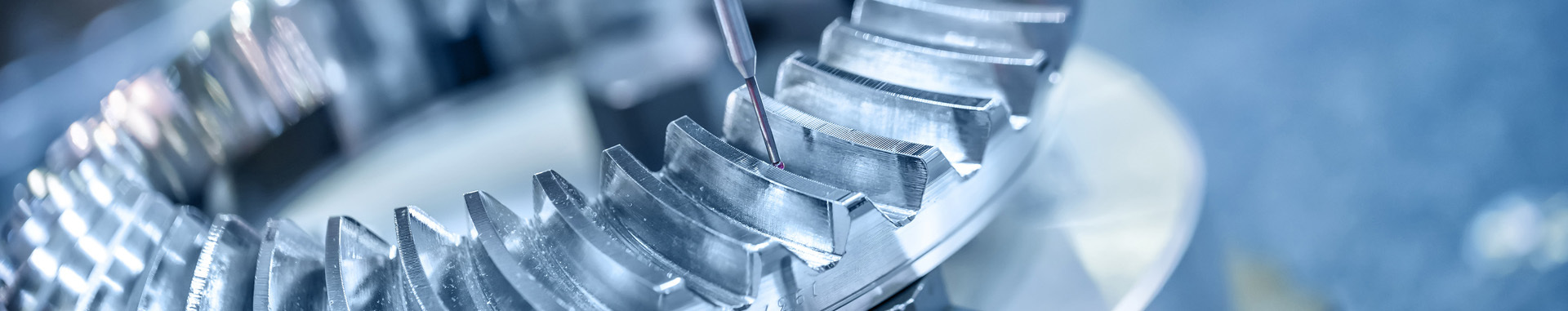

Electronic Parts Stamping Production

Metal stamping is popular with OEMs because it’s a fast and cost-effective production method for metal parts and components used in OEM machines and other finished goods. Metal stamping also produces highly repeatable parts with minimal waste, which means OEMs benefit from a lower cost per part on high-volume runs.

- Information

Electronic parts are mainly metallic or non-metallic sheets, which are stamped with the help of pressure from a press through a stamping die. Stamped parts come in large and small sizes and are cut to achieve scrap-free blanking. In actual production, due to the limitation of plate size, some parts produce a large amount of scrap during the blanking process, resulting in waste.

The service life of electronic parts depends not only on the correct mould structure, high manufacturing precision and good heat treatment effect, but also on the correct use, maintenance and care of the mould. When the edge of the convex die and concave die of the stamped part is worn out, it should be stopped in time and sharpened in time, otherwise it will expand the degree of wear of the edge of the die, accelerate the wear of the die, and reduce the quality of the stamped part and the service life of the die.

Electronic parts in the stamping process, because the surface of the material is not damaged, so there is a good surface quality, smooth and beautiful appearance, which provides convenient conditions for the surface of the surface of the paint, electroplating, phosphating and other surface treatment. Stamped parts can be divided into two categories: separation process and forming process. Separation process, also known as blanking, is aimed at separating the stamped part from the plate along the contour line, and at the same time determining the quality requirements of the separated part. The surface and intrinsic properties of the plates used for stamping have a great influence on the quality of the finished stamped products, and it is required that the stamped materials have uniform thickness, smooth and clean surfaces, no knots, no abrasion, no surface cracks, etc., uniform yield strength, no obvious directionality, good uniformity of elongation, low yield-strength ratios, and low hardenability of the workpieces.

ZK offers sheet metal stamping services in different fields:

Automotive

lithium batteries

Communications

Electronics

electrical appliances

Digital

Computers

mobile phones

Cameras

Lighting

medical instruments

Instruments

furniture

Contact ZK online for more information or submit an RFQ to get started on your project.

ZK through measure the parts to determine that the parts meet the tolerance range required, and then deliver them to customers by sea/land/air and other means of transportation according to the different packaging methods required by different customers.