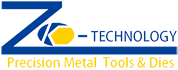

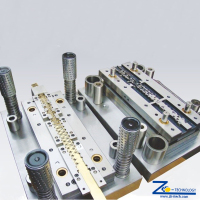

High-speed Precision Progressive Die

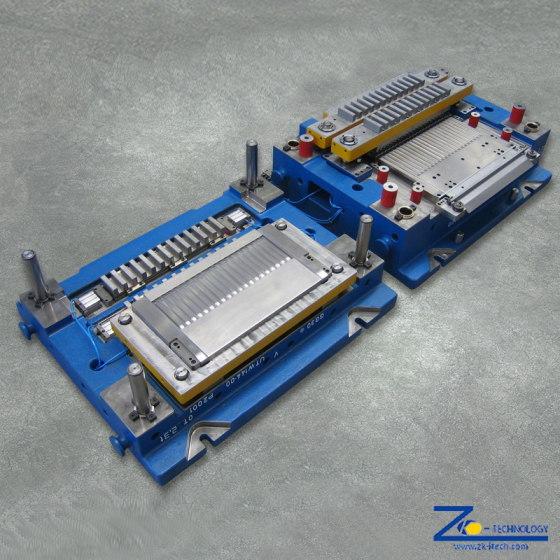

High-speed precision progressive die using servo press feed technology the feeding system pushes a strip of metal through multiple stations of a progressive stamping die. The number of stations in a progressive stamping die depends on metal part geometry and complexity.

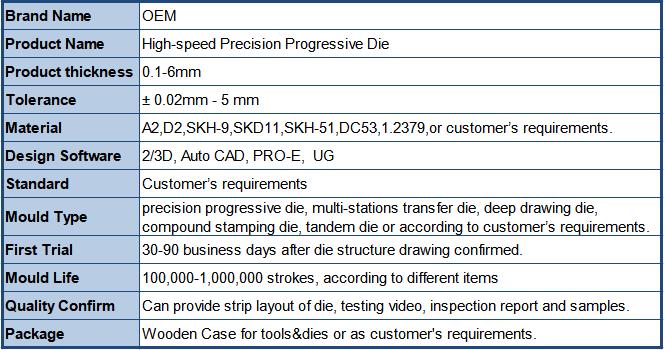

- Information

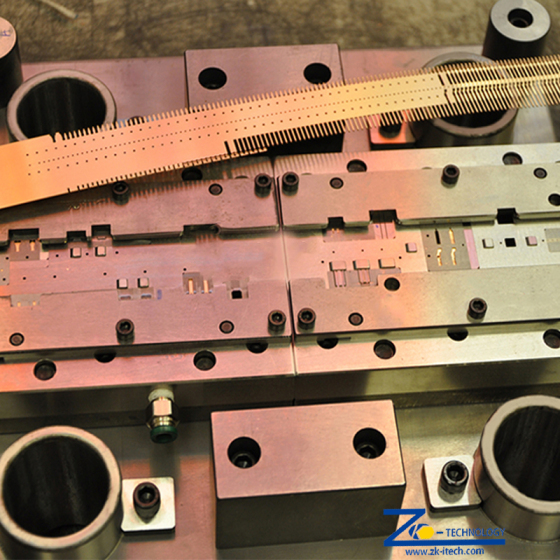

Each station performs one or more operations until a finished part is made, such as coining, punching, fine blanking, bending, shaping, cutting or drawing.

The final station is a cutoff operation, which separates the finished part from the carrying web. The carrying web, along with metal that is punched away in previous operations, is treated as scrap metal. Both are cut away, knocked down and then ejected from the die set.

Progressive stamping dies are highly complex and must advance and secure a strip of metal in a specific location with precise alignment to allow for proper timing and interaction of the upper and lower tools, pads and carriers.

Our advantages

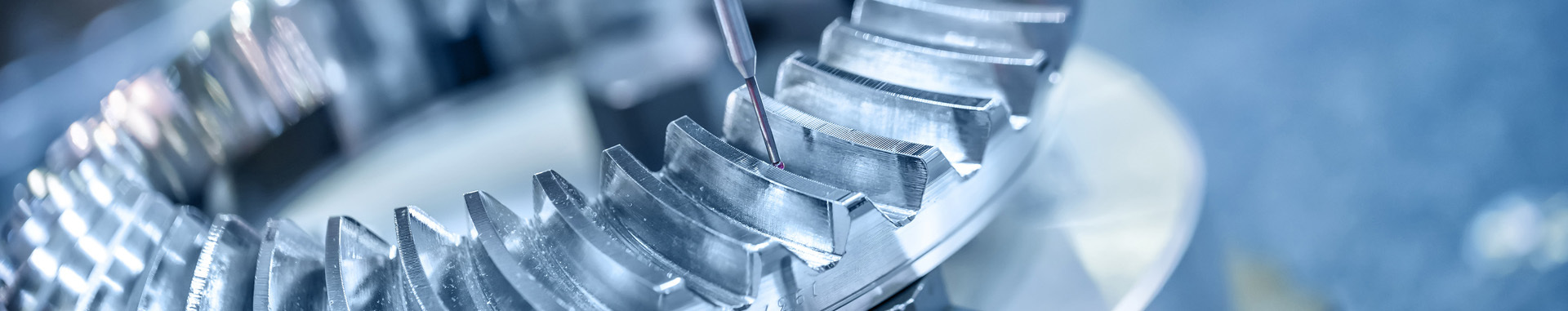

Professional development and design ability

We have an experienced research and development team, and complex, difficult molds can be rapid molding and design accurately.

Quality assurance

The company has advanced testing equipment and strictly implements ISO9001 and IATF 16949 certification.It is possible to eliminate any quality problems in production.

Accurate delivery

We have the first-class advanced processing equipment, effectively ensure the rapid response and efficient service.

Business introduction

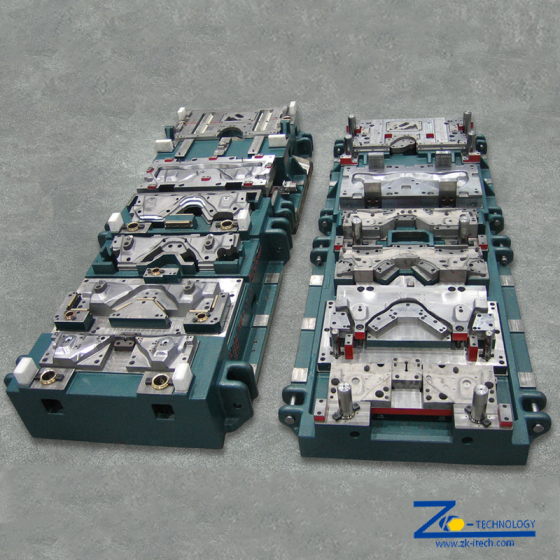

ZK specializes in designing and producing of various metal stamping tooling, and is good at producing the precision metal stamping parts.

Our company is developed steadily since its establishment with the hard work of the professional designers and all the other staffs. Nowadays, we are able to produce different kinds of hardware stamping tooling and auto-parts stamping tooling, like progressive tooling, continuous drawing tooling, machine-hand transfer tooling, etc. We are well experienced in producing tooling for stamping machines' capacity from 60 Tons till 800Tons.

At present we are able to undertake the batches of tooling development business, especially plenty experience and mature technology in designing and producing auto-parts and electric appliance parts. We will provide series service in tooling designing, developing, producing and parts production. In order to meet the developing requirements of our customers, we import the advanced machinery and the qualified technicians timely.